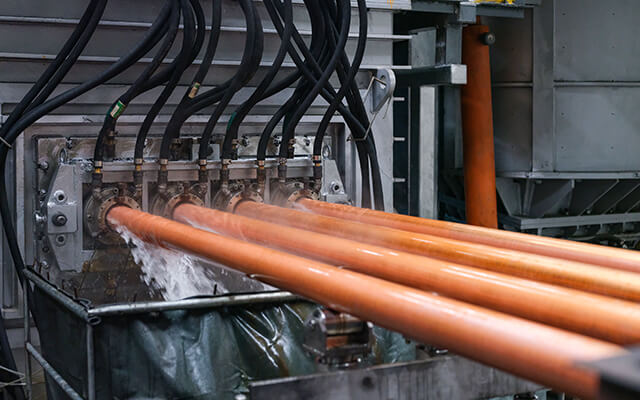

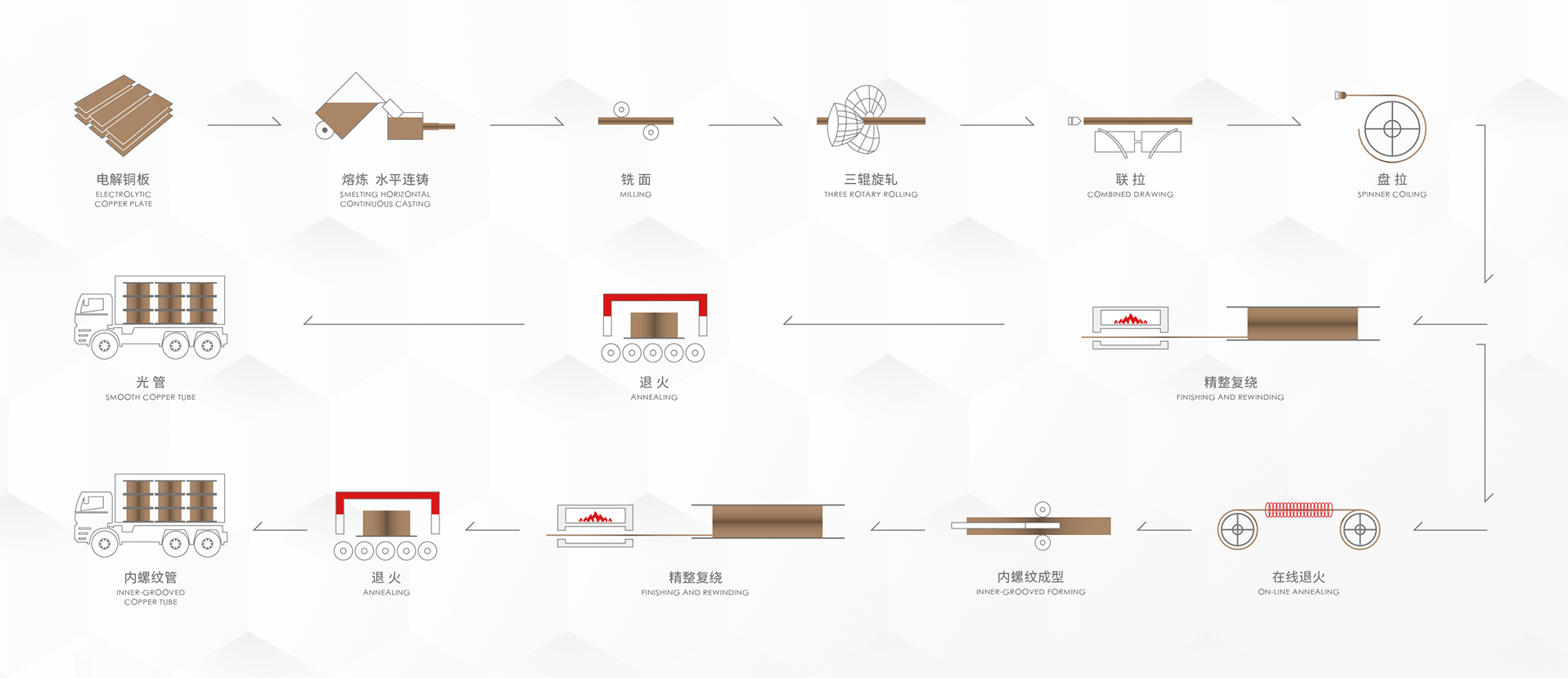

Smelting Horizontal

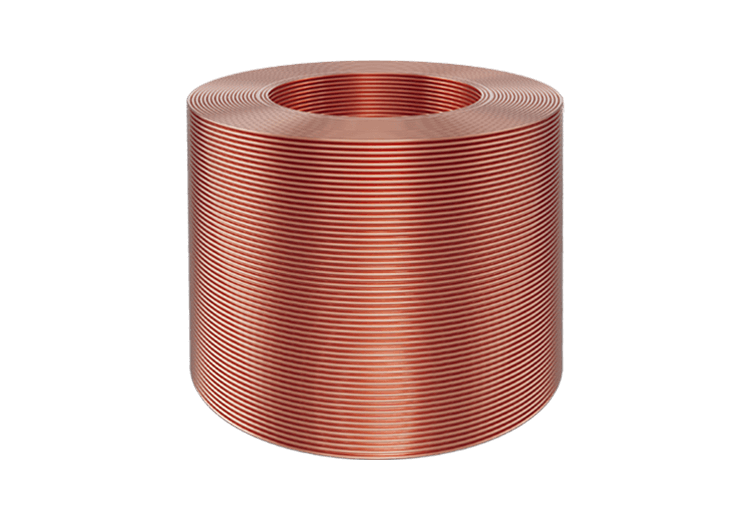

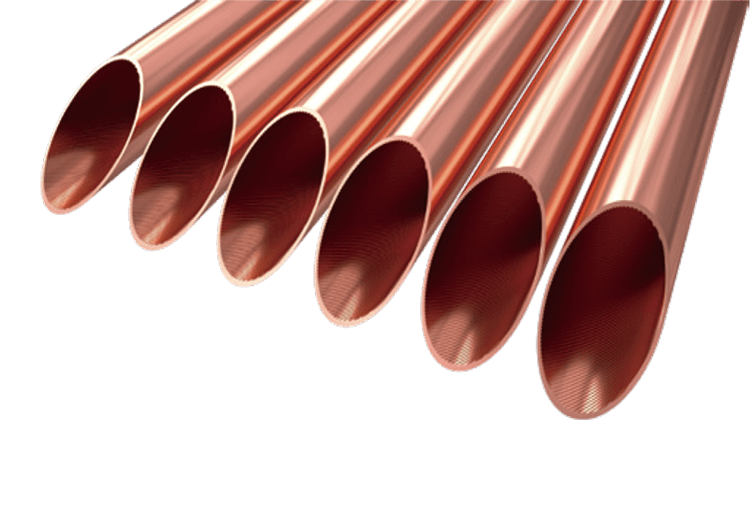

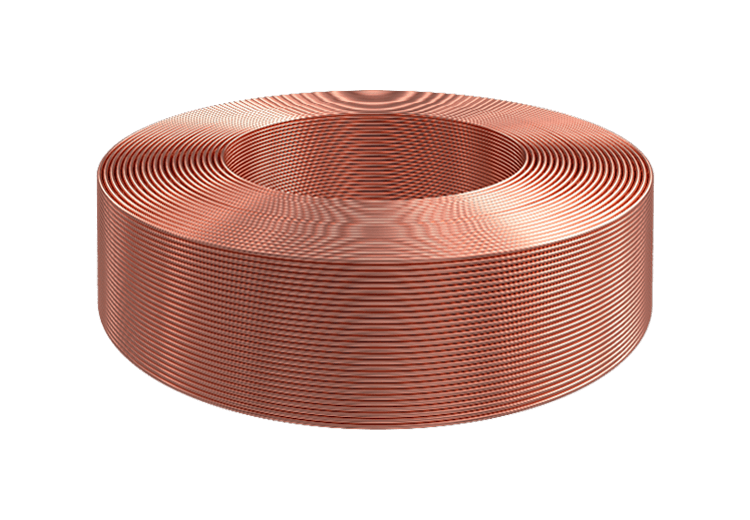

The dried electrolytic copper is added to the core power frequency melting furnace to heat and melt, and the casting begins at about 1180℃. The copper liquid solidifies and forms in the graphite mold of the crystallizer. The drawing machine of horizontal continuous casting continuously draws ingots according to the set casting frequency and speed, and the tube blank is measured by the flying saw.